Why Water Filtration is Important for Beer Brewers

API Vote For Slainte Vote4Energy

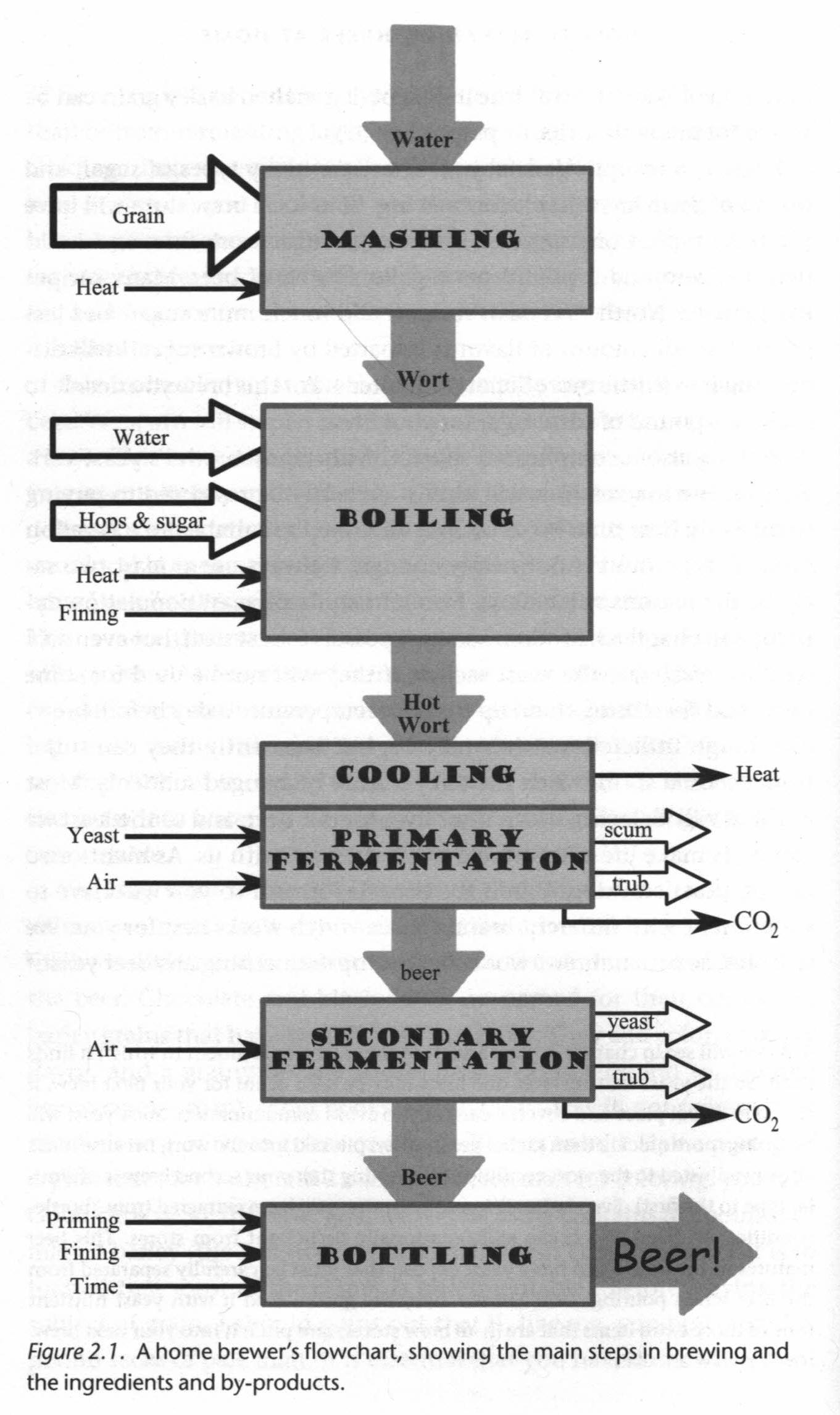

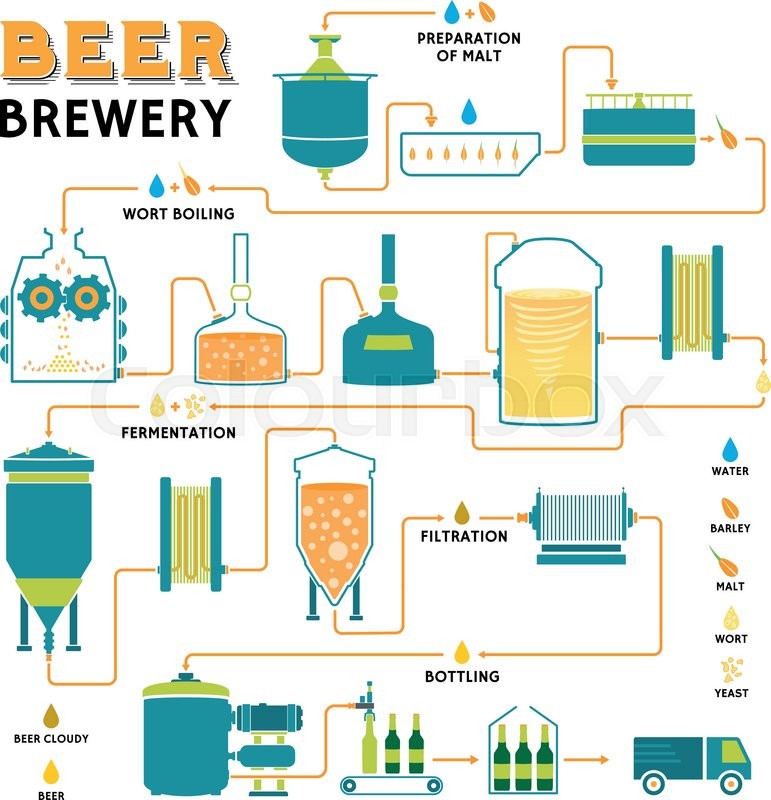

The brewing process can be broken down into four simplified steps: Mashing, separation, boiling, and fermentation. The four beer ingredients are brought together in each of these steps to create an enormous range of beer styles. The darkest stout and the lightest pilsner are made from the same four ingredients: Water, malt (or other grains.

The Brewing Process Brewing process, Brewing, Craft beer tasting

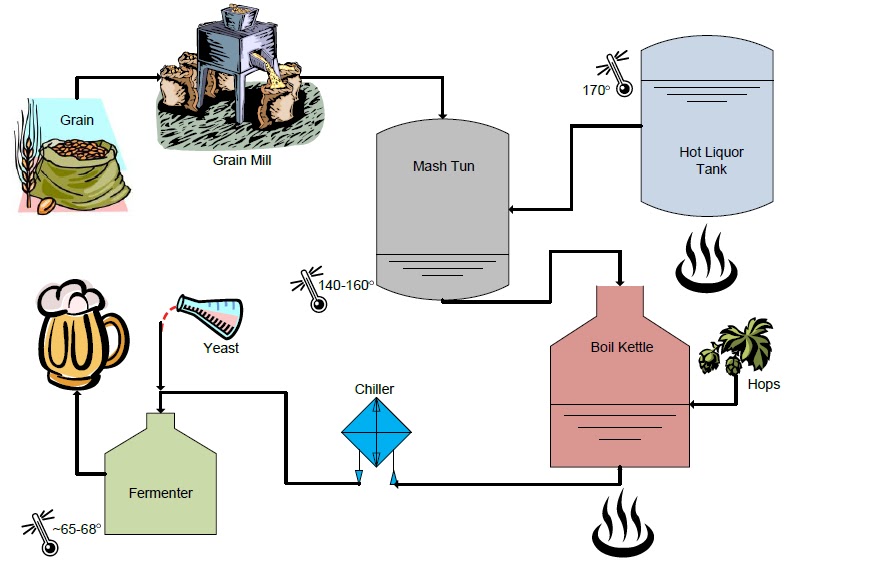

The Basic Process Equipment Crushed Grains All Grain Brew Steps 1. Heat Strike Water 2. Doughing In 3. Mash (Saccharification Rest) 4. Mashout (Raising the Grain Bed to 168°F) 5. Vorlauf/Recirculate 6. Sparging (Continuous Sparge or Batch Sparge) Calculating Sparge Water Simple Batch Sparge (Double Batch Sparge) Fly Or Continuous Sparging 7.

CBrewmaster About Us

1. Cleaning & Sanitizing Once you have all of the necessary equipment, the first step isn't actually brewing at all. First, you'll need to thoroughly clean and sanitize ALL of your equipment. This step is crucial. Do not take any shortcuts here.

Brewing Process Poster nuflux media

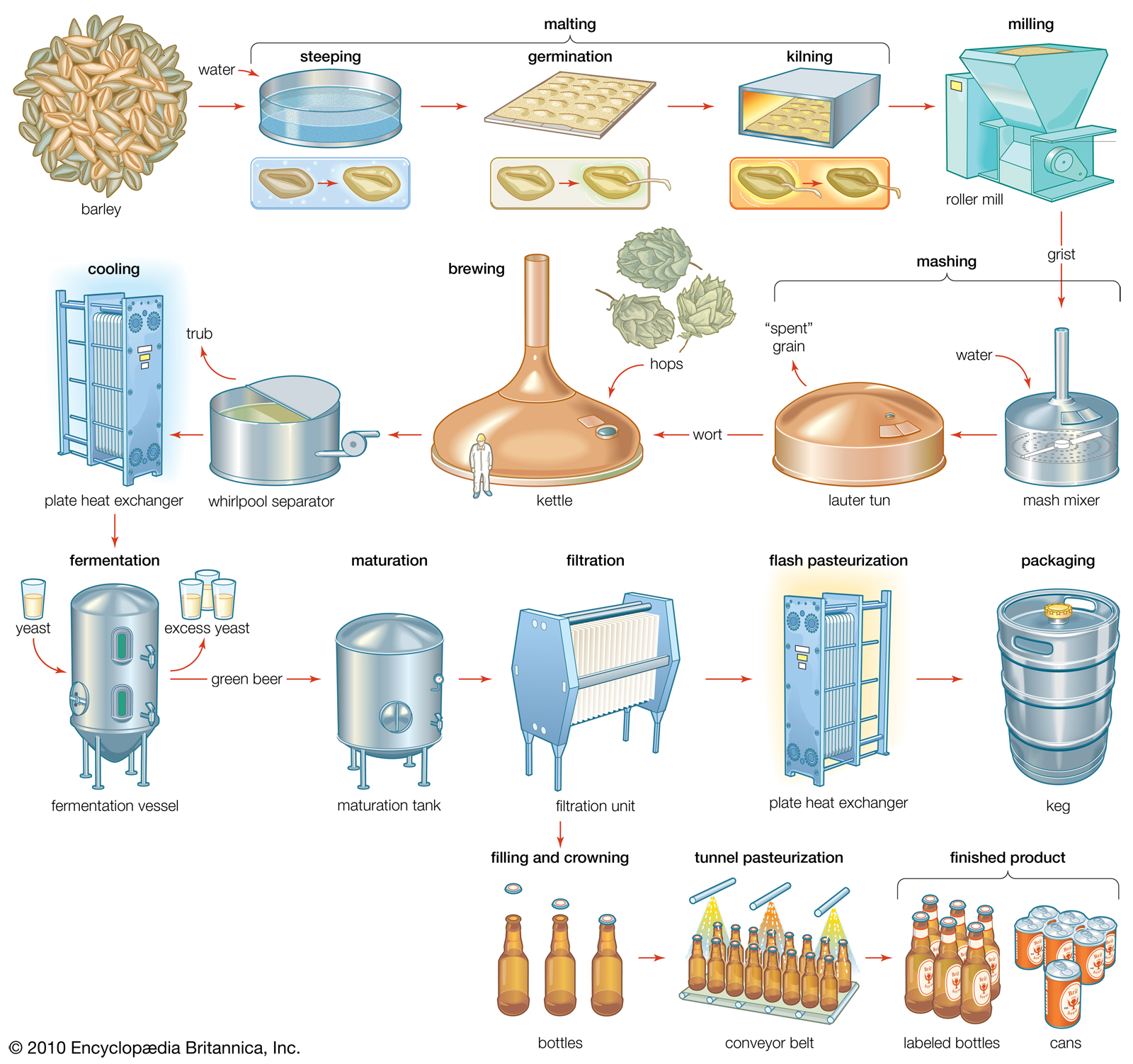

06/22/2023 Malt Brewing begins with raw barley, wheat, oats or rye that has germinated in a malt house. The grain is then dried in a kiln and sometimes roasted, a process that usually takes place in a separate location from the brewery.

Why Water Filtration is Important for Beer Brewers

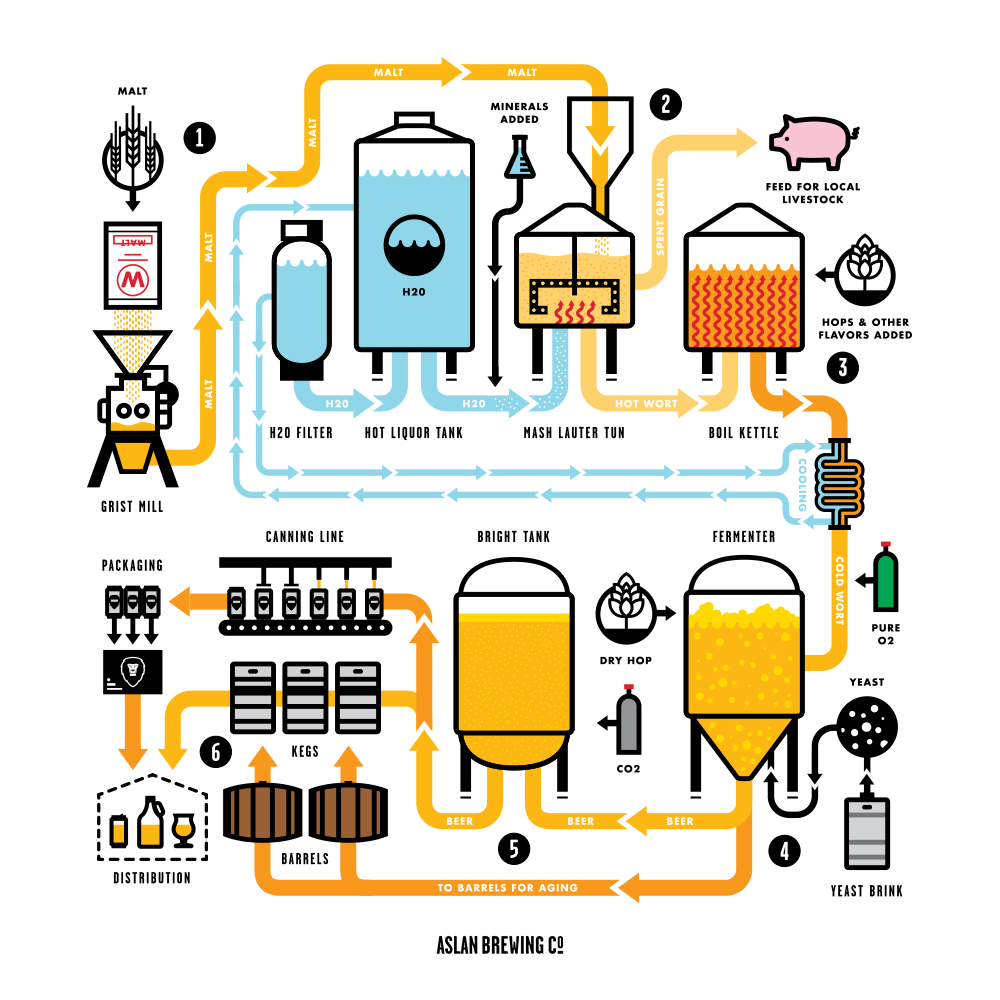

June 1, 2013 By Jay Brooks Today's infographic is another diagram of the Brewing Process, this one from the Beer Masons, a beer appreciation society in Australia. Click here to see the diagram full size. One interesting addition is they point out that beer is known by many names in the process from grain to glass, and list them in a flowchart.

Brewing Process Smoky Mountain Brewery

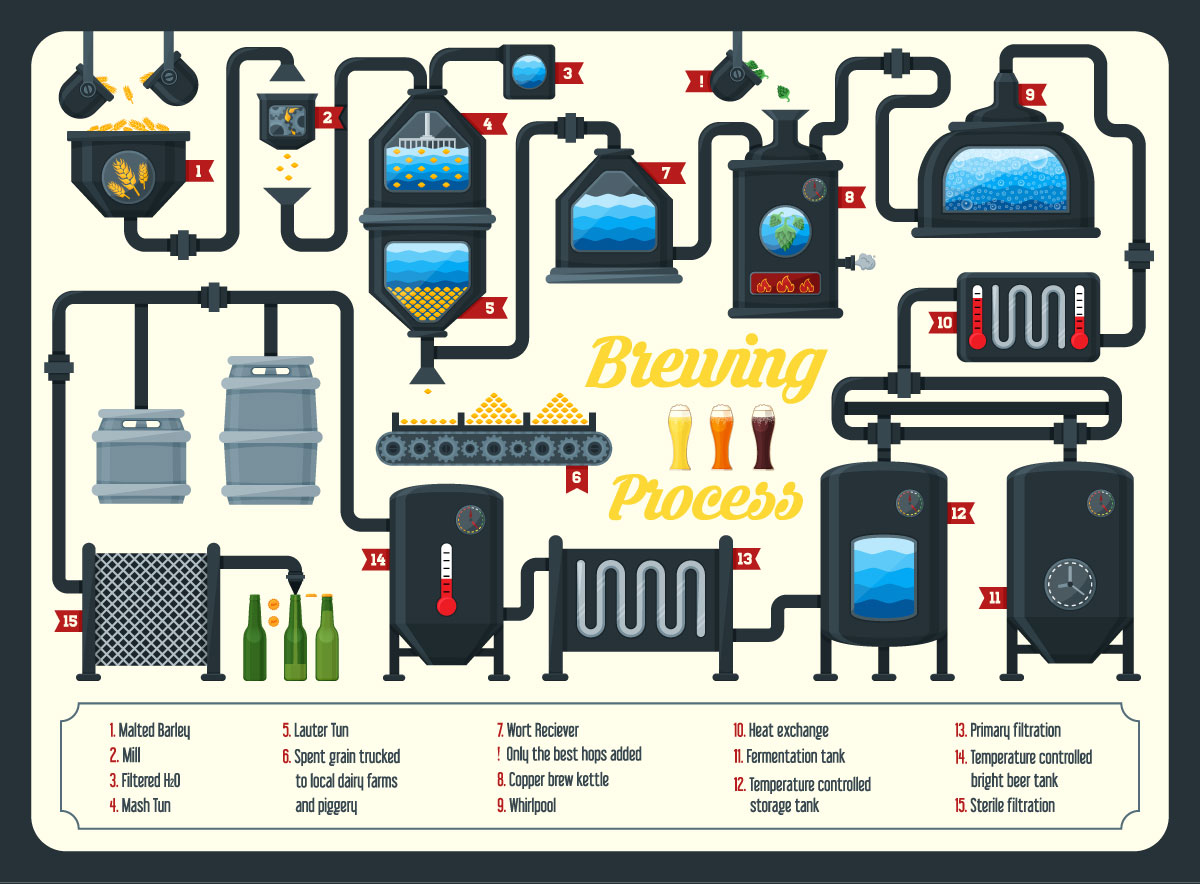

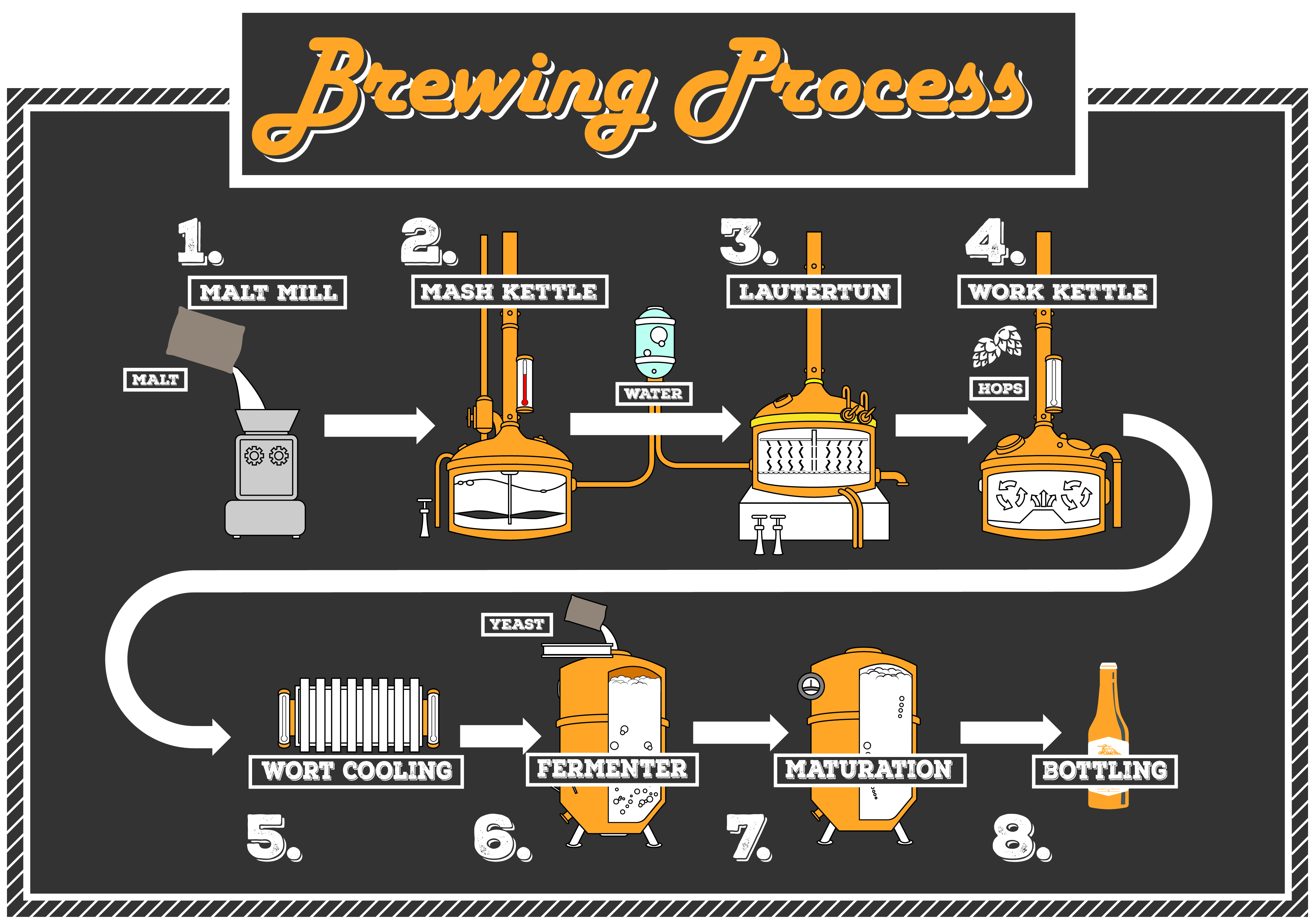

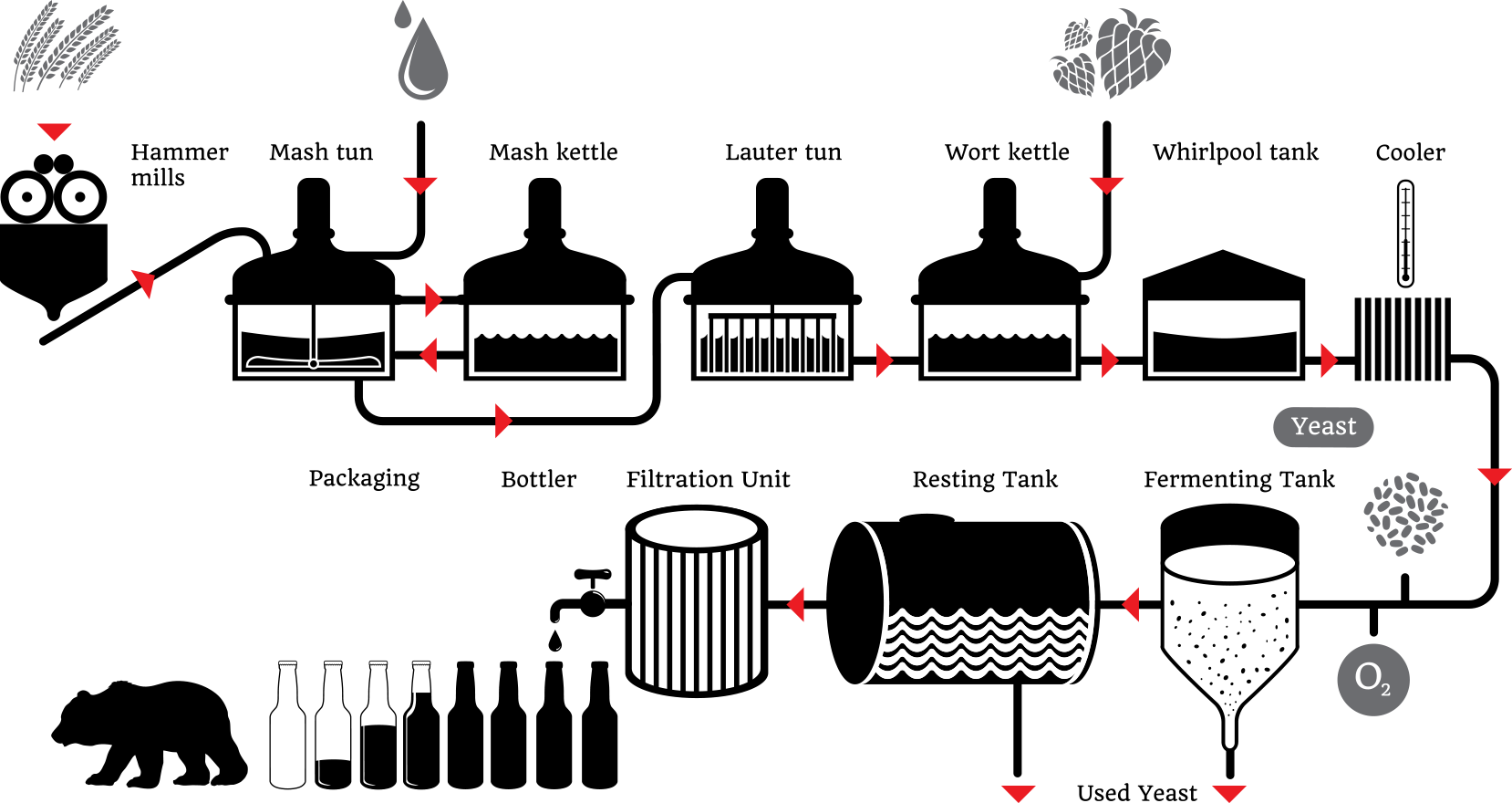

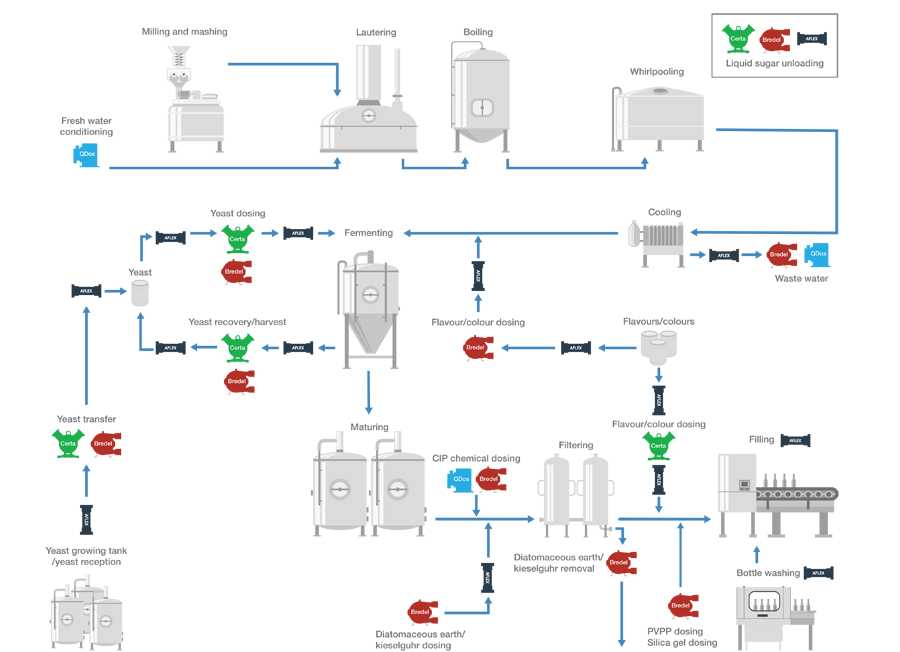

Steps in the brewing process include malting, milling, mashing, lautering, boiling, fermenting, conditioning, filtering, and packaging. There are three main fermentation methods: warm, cool and spontaneous. Fermentation may take place in an open or closed fermenting vessel; a secondary fermentation may also occur in the cask or bottle.

The Brewing Process Beer Brewing Process, Home Brewing Beer, Beer Tanks

The brewing process diagram is a great way to see how beer is made and to get an understanding of the different steps involved. It's also a handy tool for those who are new to brewing. If you're new to brewing, or just want to get a quick understanding of the brewing process, then a brewing process diagram is a great place to start.

Image result for brew process diagram uk Brewing process, Brewing

Beer is an incredibly popular drink, and it's fascinating to learn about the steps that go into making it. Did you know that after tea and coffee, beer is th.

The Hop Daddy's Beer Blog The brewing process

1 449 Post Recommended Templates This Brewing process diagram depicts malting, milling, mashing, extract separation, hop addition and boiling, removal of hops and precipitates, cooling and aeration, fermentation, yeast separation from young beer, aging, maturing, and packaging.

Brewery process vector illustration. Labeled beer ale making process

Step 1: Malting. The first main step in the brewing process is known as the malting phase. Every beer contains some type of grain. Barley is the most popular, but many brewers use wheat and rye as a substitute. These grains are dried out and cracked in a heating process.

Brewing industry Brewery pumps WMFTG Food & Beverage

This is a detailed, step-by-step guide to the beer-making process. It covers wholegrain brewing and brewing with a malt extract. This post is part of a series of posts on the beer-making process. See Homebrewing 101 for detailed information on the equipment, ingredients, sanitation, and recipes.

Brewing process, Beer brewing process, Brew your own beer

Grain Beer production begins with malting grains. Barley is the most common grain in beer, but some recipes include wheat, corn, and rice. The beer you brew by adding any grains is well-known as all-grain beer. You can store whole grains for months before brewing. Once you crush or mill them, you need to use them as soon as possible.

Beer History, Production, and Regulations 2259 Words Research Paper

The Malting process Brewing beer begins with grains, usually barley, although oats and wheat can also be used. The grains are harvested and processed through heating, drying and cracking, to isolate the enzymes used in beer. The malt used determines the colour of the beer.

Beer Physics Introduction

Beer is an alcoholic beverage produced by extracting raw materials with water, boiling (usually with hops), and fermenting. In some countries beer is defined by law—as in Germany. Brewing in the 21st century is a large-scale industry. Learn about the history, types, and brewing process of beer.

Black Alley Brewing A Primer In Brewing

Are you a beer enthusiast looking to take your brewing skills to the next level? If so, visualizing the beer brewing process through a comprehensive diagram can be a game-changer. Understanding the step-by-step journey of how your favorite beverage is crafted can provide invaluable insights and help you perfect your own brew.

Brewing; beer production process

Milling To make beer we need sugar, we get it from malted barley. The fermentable sugars needed are contained inside the husk of the kernel. It's actually starch at this point. We need to crack open this husk to expose the starch for conversion. When looking to order a mill for brewing, it's best to get one with adjustable rollers.