The Essential Considerations to Build a DryAging Room Metro

DivePigs BBQ Dry Aging Beef

Aging on a large scale. Dry Aging Walk-in Chambers from DRY AGER. Made in Germany. With the maturation cell series, DRY AGER ® offers customized solutions that are available from 100 x 100 cm to 600 x 600 cm (W x D) and in different heights. Suitable for you! Choose from different design concepts and surfaces, colors and interior fittings as well as the desired maturation techniques and controls.

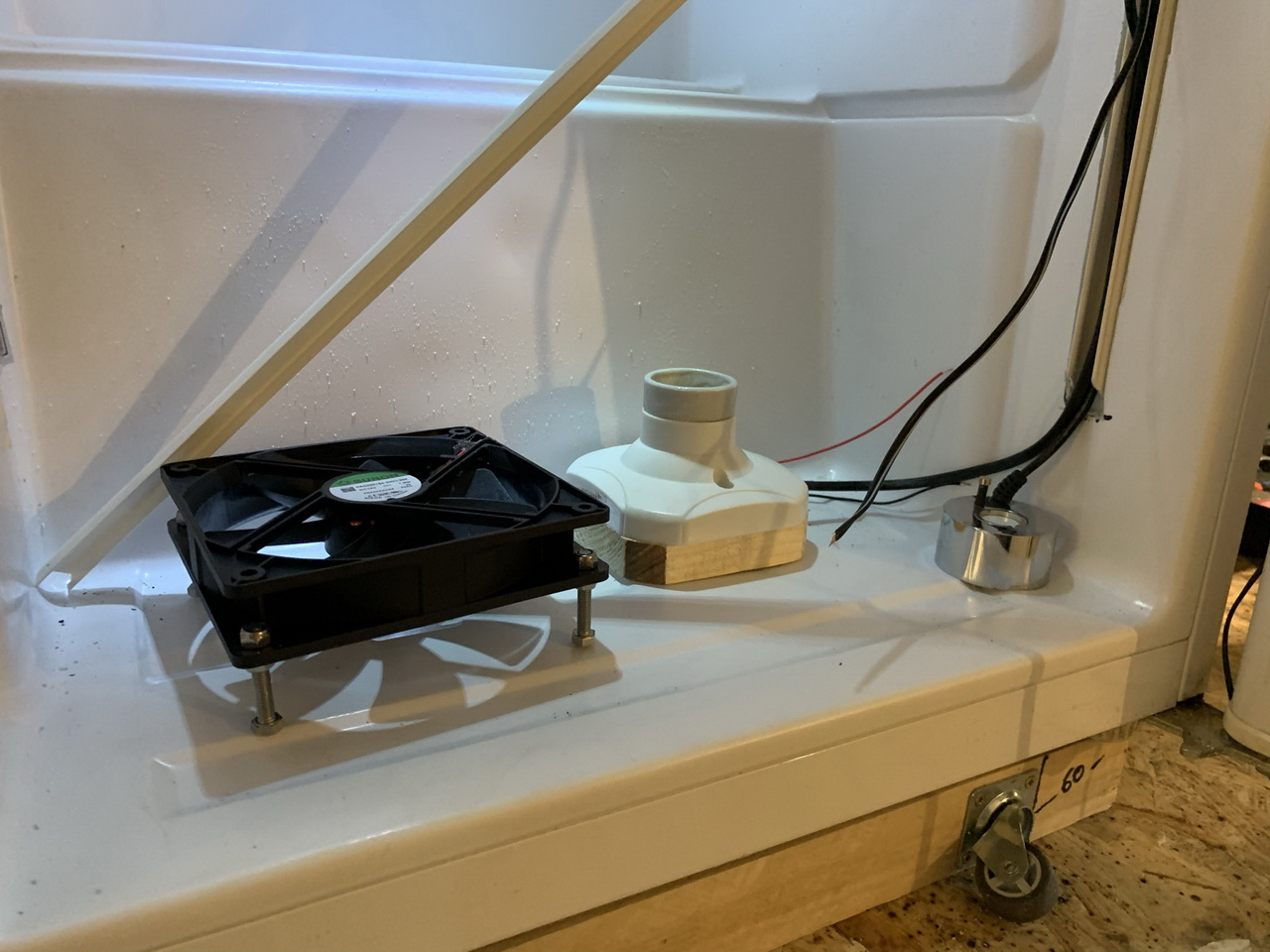

Dry Aging and Curing Chamber III Version 2 Farcyde's Stuff

Climate stability is critical for Dry Aging perfection, consistency, and safety. Germs, bacteria, and mold don't stand a chance. Every 60 seconds the air is re-circulated and pristinely sterilized. The antibacterial inner layer in the chamber does the rest. Dry Aging has never been so safe, seamless or worry-free. EASE OF USE

Dry Aging Walkin Chamber Aging Room DRY AGER®

When the meat is placed in the controlled chamber exposed to air, the moisture is pulled out and the natural enzymes in the beef break down the muscle slowly over time. This process is what makes the meat more tender. Once the surface of the meat dries the inside of it stays moist and red. Another part of the dry-aging process is the other.

How To Store Dry Aged Steak Storables

It doesn't smell fishy at all. This, Liao says, is because dry-aging fish removes the moisture, including residual blood and slime, that creates a fishy odor. Dry-aged fish is cleaner fish. It.

- Copy.jpg)

The Aging Room Premium DryAging Chamber Using Salt DryAged Meat

Test (Without meat) -You can place some paper towels with some water splashed on them, or a sponge in a bowl to mimick the freshly cured meat, which will be 70% water content to start. The goal of between approx. 70-80% Humidity, and 50-59F/10-15C for dry curing meat.

Dryaging to improve palatibility in cull cow beef The National

The most affordable, reliable and expandable home dry-aging system. Enjoy amazing dry-aged steaks anytime and save up to 75% off of retail and restaurant dry-aged steaks. Every PRO 40 comes with a built in refrigeration system and computer controlled air circulation that creates a microclimate ideal for dry-aging beef or making charcuterie at home.

DRY AGER® Dry Aging Meat Fridges & Dry aged beef, Aged

At The Aging Room, our dry-aging chambers come equipped with a wall of pink Himalayan salt bricks. Using our patented techniques, the Himalayan salt wall helps eliminate any unwanted bacteria from the room and strengthens the flavor of the meat. To protect the chamber, the coating of the chamber wall is completely salt resistant.

Today

Aging meat properly can bring added flavor and tenderness to meat and the DRY AGER UX1500 PRO meat curing cabinet ensures that your meat is aged to perfection in a precisely controlled environment. Using UXAirReg technology, this cabinet maintains a perfectly stable microclimate without the need for water connections or drains making it easy to install and use. It has a temperature range from.

Dry Aging and Curing Chamber II Next Steps and Information Farcyde

Our monitoring App is ready to download and connect. The PRO 15 is designed so that you can slide in our Horizontal Truss Rack (available as an accessory) for the ultimate easy dry-aging experience. Dimensions : 10" (H) x 11.5" (D) x 15" (W) - 38cm (W) x 30cm (D) x 25cm (H) Delivery: 10-14 days from date of order.

The Essential Considerations to Build a DryAging Room Metro

Unless your refrigerator is odor-free, a mini fridge is the best possible option. A fan. To promote drying of the surface and even aging, you want to stick a fan inside your fridge to keep air circulating. This works in much the same way as a convection oven, promoting more even cooling and humidity all around.

Digital Dry Curing Chamber for AtHome Use DIY Dry Aging

Maximum flexibility. The included stainless-steel hanger and optional shelves for meat and charcuterie, allow you to dry age up to 100 kg of food at a time. With the DRY AGER DX 1000 Premium S, however, an aging cycle really pays off, with a pay-off period of no more than 6 months in a business setting. Buy now Data Sheet.

What is dry aging DRY AGER THAILAND CURATING DRAMATIC EATING EXPERIENCES

PREMIUM QUALITY DRY-AGING AT HOME: SteakAger PRO 15 enables you to enjoy premium quality dry aged steaks at home using our in-fridge meat curing chamber. Transform your grocery beef into steakhouse quality mouthwatering custom dry-aged steaks and treat your friends and family. ALL IN ONE SOLUTION: Just unwrap and use!

Introducing the Latest Dry Aging Production Units Range Dry Ager

The ideal range for dry curing beef is 32 to 35°F (0 to 2°C). This low temperature slows bacterial growth and promotes enzymatic reactions that are necessary to break down meat proteins and improve flavor. 2. Humidity. The humidity level in the chamber must be carefully controlled and is usually maintained at 85-90%.

Dry Aging and Curing Chamber III Version 2 Farcyde's Stuff

At The Aging Room, we believe dry-aged beef is the ultimate expression of steak. Our background is in technology, and we have discovered new methods to apply modern processes to recreate traditional and natural ways of crafting quality meats with superior taste.. Without additives, chemicals, or any other artificial means of dry-aging, we help you provide customers with the experience, and.

Why Himalayan Salt in the DryAging Room? The Aging Room DryAging

The unit can safely age up to 40lbs of beef (2 full subprimals), perfect for those wanting to dry-age larger quantities, stagger aging cycles, or experiment with your favorite cuts. Monitor your dry-aging experience at any time with our mobile app where you can track length of age, temperature and humidity. Width 18.875" Depth 18.25" Height 33..

Dry Aging and Curing Chamber II Next Steps and Information Farcyde

The Original - from the No.1 brand worldwide. Dry Aging Cabinets, Dry Aging Walk-in Chambers, and Dry Aging Production Units. Quality Made in Germany. Timeless modern design on the outside - high-precision, sophisticated technology on the inside. Craftsmanship meets high-tech. Produce dry-aged meat, poultry, fish, sausage, ham, and cheese.