Steel Sheet Metal Stamping Punching Press Machine 160ton Mechanical Power Press Machine China

Steel Sheet Metal Stamping Punching Press Machine 160ton Mechanical Power Press Machine China

The gap press illustrated in the figure has a gap like opening in the frame for feeding the sheet metal from one side of the press. The frame is attached with the base and provides a rigid construction. Inclined Press. The inclined press illustrated in the figure is the most common type of press used in industry.

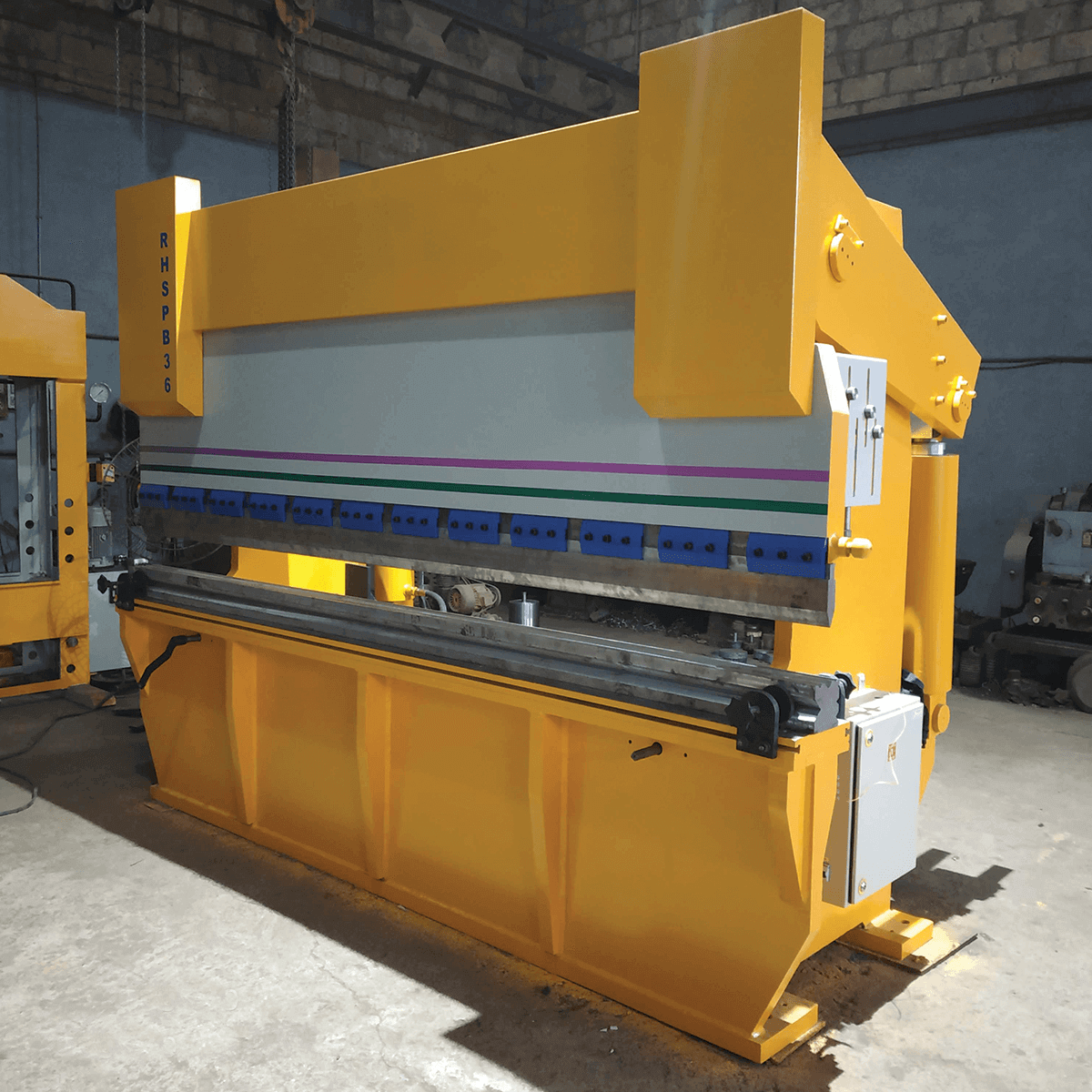

hydraulic sheet metal brake press 300 ton 5000mm ACCURL

Choose from our selection of compact bench-mount lever presses, bench-mount air-powered presses, wall-mount presses, and more. In stock and ready to ship. BROWSE CATALOG. Abrading & Polishing; Building & Grounds;. Save space in your shop by cutting, bending, and curving sheet metal with a single machine. Also known as shear brake rolls.

12" Combination 3 in 1 Sheet Metal Machine ShearBrakePress

What is a metal forming press? A metal forming press, also known as a stamping press, is a machine tool used to precisely shape and cut metal typically using upward and downward movements. Metal, supplied in sheet, coil, or tube form, is pressed between two halves of a press tool.

Hydraulic Press Brake Machine Sheet Cutting Sheet Metal Cutting Maximum Tonnage 20 To 500

19 $33999 FREE delivery Jan 11 - 16 Only 1 left in stock - order soon. Small Business KAKA INDUSTRIAL EB-4816M 48-Inch Magnetic Sheet Metal Press Brake, 16-Gauge Mild Steel Capacity, 6-ton magnetic power, bend boxes or pans to any depth 220V-60HZ-1PH… 8 $2,71999 FREE delivery Jan 11 - 16 Only 14 left in stock - order soon. Small Business

Sheet Metal Press Tools, Electric Hydraulic Presses by Woodward Fab

Our sheet metal press product range includes hand operated, hydraulic, and electric hydraulic presses. With our presses, you can shape, punch, and stamp metals of various sizes. They are also capable of working with metals of various thicknesses. Presses Product Range Shop Presses

100 Ton High Speed Sheet Metal Punch Press Machine for Sale China 100 Tong Hydraulic Press and

Metal stamping is a cold-forming metal fabrication method that uses pre-shaped dies and pressure to shape sheet metal blanks into products and components. Using automated or manual feeders, manufacturers insert metal sheets into the stamping press between the tool and die surface.

Sheet Metal Press Brake CNC Controled Bending Machine 400T

We cut all our metals to size! Lowest prices guaranteed. Call for better pricing. We Offer Reliable Service at Low Prices, Guaranteed. Will call locations. Shop now.

52" Combination 3 in 1 Sheet Metal Machine ShearBrakePress SBR5220

Swaging Rounded Metal. Also a way to flatten metal, this process is typical used to make wires more thin so that they can more easily fit into an opening. At OAK Press Solutions, we manufacture 30 to 300 ton mechanical presses for the general sheet metal stamping industry, with the capability of setting up turnkey systems for our customers.

Press Brake Tooling Enables High Quality Sheet Metal Forming Metal Working World Magazine

The difference between steel sheet and plate lies in their gauge or thickness. Plate metal thickness includes steel sheet metal that is 5mm or thicker. Steel plate is often used for construction or structural purposes due to their low maintenance versatility. Advantages. Corrosion-resistant.

J23 100 Ton Eccentric Power Press Sheet Metal Perforating Machine,Aluminum Sheet Punch Press

7 Products Floor-Mount Combination Presses, Punches, and Shears Also known as a 40-ton metalworker, these hydraulic machines handle a variety of forming tasks including pressing, punching, notching, and shearing. The safety guard complies with ANSI B11. 8 standards.

Sheet Metal Stamping Power Press Machine 200T PLC Control

Patreon Link: https://www.patreon.com/user?u=889861Instagram Link: https://www.instagram.com/craigsmachineshop/Please direct all correspondence to:Craig's Ma.

High Speed Press Machine , Sheet Metal Punching Machine ISO 9001 Certification

A multi press machine is a great solution for working with heavier thicker metal by interchanging optional tooling for low to medium volumes and is cost-effective as well. The press design offers 3 tons of manual pressing power to handle shearing up to 1/16" thickness and bending up to 3/16" thick. The Woodward Fab Sheet Metal Forming Press.

63 Ton Full Automatic CNC Hydraulic Sheet Metal Press Brake Machine

Steel sheet and plate products are manufactured from different steel grades, each providing unique qualities and beneficial features. Whether you are searching for hot rolled, cold rolled, galvanized, tread, or a host of other steel plate and sheet metal options and services, there is a steel plate or sheet metal option that matches your project's unique specifications.

0.5 Mpa Metal Stamping Press Machine , Stainless Steel / Aluminum Sheet Metal Stamping Machine

Straight Sheet Metal Brakes; Sheet Metal Shears. Foot Sheet Metal Shears; Hydraulic Sheet Metal Shears; Manual Sheet Metal Shears; Pneumatic Sheet Metal Shears; Slip & Plate Rolls.. Metal Bench Press . Hydraulic Press . Louver Press . Press Tooling & Accessories . My Wish List. Last Added Items. Add to Cart Add to Cart. Remove This Item.

H Frame Double Crank Sheet Metal Punch Press Machine China Punch Press Machine and Press Machine

Metal forming and press-brake bending is done in-house using steel plate, sheet metal and other structural shapes, such as tube bending and pipe bending. We are currently serving customers in Orange County, Los Angeles, San Diego, San Bernardino and across the nation.

JH21 Power Industrial Metal Stamping Machine , 2450KG Metal Punch Press Machine

Save space in your shop by cutting, bending, and curving sheet metal with a single machine. Also known as shear brake rolls. Use the blade on the shear to make clean, straight cuts; it has two cutting edges for twice the life. A press brake makes bends up to 90°. Create curves and circles with the slip roll.. When using the shear or press brake, set the manual back gauge to precisely position.