Builtconstruct Different Castinsitu Methods of Bridge Construction

SPAN BY SPAN CAST IN SITU BRIDGE

WHAT IS SITE CAST CONCRETE? As opposed to precast, site cast, sometimes known as in-situ concrete, is poured, molded and cured on site. Like precast concrete, on site concrete is formed in a mold and then lifted in place. However, one of its advantages over precast slabs is that it does not need to be moved far to be lifted into place.

Bored cast in situ

Definition of Cast-in-situ Concrete. The quality of site-cast concrete is also dependent on various factors such as workmanship, how concrete was prepared, parameters of concrete like water-cement ratio, uses of admixtures, type of mixing, etc., Curing process, weather condition, humidity, temperature, etc.

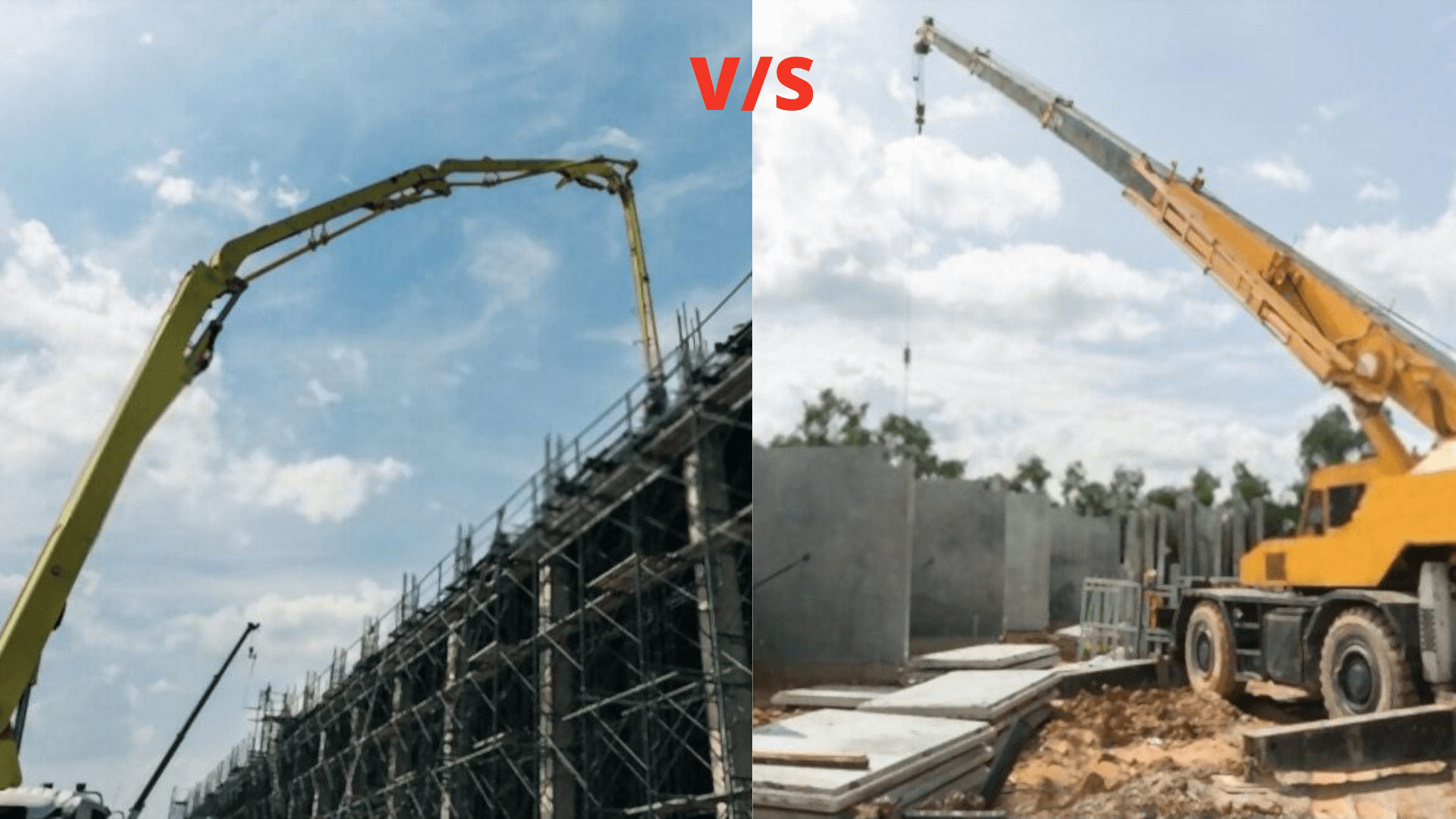

Cast in situ or Precast Concrete! Which one is a Better method Civil Rack

Cast-in-place concrete walls derive their thermal performance characteristics primarily from the amount of insulation placed in the cavity or within the backup wall. Moisture Protection. The most common moisture protection system used with cast-in-place concrete wall systems is a barrier system incorporating an adequate joint seal.

Castinsitu driven piles De Waal Solid Foundations

Cast-in-situ concrete is a construction method that involves pouring fresh concrete into a specific mould or formwork at the construction site. Unlike precast concrete, which is cast and cured in a controlled environment before being transported to the construction site, cast-in-situ concrete is mixed and poured on-site.

Cast InSitu Lining with EPC's Synthetic Fiber Concrete Reinforcement (1)_web Barchip

Driven cast in-situ piles are instrumented during the installation process to provide high quality records during the construction process. A robust testing schedule also demonstrates the high performance/quality standards achieved. Driven cast in-situ (DCIS) piles are constructed by driving a closed-ended hollow steel or concrete casing into.

Castinsitu driven piles De Waal Solid Foundations

Types of Uncased Cast-in-Situ Concrete Piles Following are the different types of uncased cast-in-situ concrete piles and their uses: Simplex pile; Frankie pile; Vibro pile; Pedestal pile; Simplex Pile Simplex pile is useful for both soft and hard soils. To obtain simplex pile, a steel tube with cast iron shoe is driven into the ground up to.

Cast Insitu Kerb and Channel, Slipform TIL

Precast concrete is cheaper for a large construction project, while cast-in-situ concrete is cheaper for a small project like a single house. Why is precast concrete better than cast-in-situ concrete? Precast concrete is better than cast-in-situ concrete for every factor, such as superior quality, lower construction costs, a wider choice of.

Piling services driven, cast insitu (DCIS) piles Keller UK ESI External Works

Precast concrete components are ready for immediate use upon delivery while cast-in-place concrete are not. This eliminates unnecessary time needed to set up cardboard forms, bend and position rebar, pour and vibrate concrete and then wait for the concrete to cure. The removal of these steps saves valuable time in terms of project duration and.

Castinsitu driven piles De Waal Solid Foundations

Practice oriented papers and articles ON CAST IN SITU PILES. In-Situ Properties of Concrete Piles Repaired Under Water. Publication: Concrete International. Date: 3/1/1992. Deterioration of Reinforced Concrete Wharf. Publication: Concrete International. Date: 3/1/1981.

cast insitu concrete walls are imprinted with the grain of their timber formwork Architecture

Abstract. An essential difference between concrete and other materials used in facade construction is that concrete is poured in place into moulds, or into formwork, rather than being manufactured as a standard size component in a factory. Whereas metal, glass, masonry, plastics and timber are made to standard dimensions in the form of sheets.

CastinSitu Pile Golden Eagle Networks LTD

Cast-in-place concrete or Cast-in-situ concrete is a technology of construction of buildings where walls and slabs of the buildings are cast at the site in formwork. This differs from precast concrete technology where slabs are cast elsewhere and then brought to the construction site and assembled.

RCC Pile concreting cast in situ method YouTube

3.Cast-in-Situ Post Tensioned Method. Cat-in-situ Post tensioning method of bridge construction is more demanding method because of its durability and applicability to complex bridge curves etc. In this method along with concrete and reinforcement, steel strands or tendons are also used to introduce post tensioning.

Cast in Situ MSM Construction

For example, concrete slabs may be in situ (also "cast-in-place") or prefabricated. In situ techniques are often more labor-intensive, and take longer, but the materials are cheaper, and the work is versatile and adaptable. Prefabricated techniques are usually much quicker, therefore saving money on labour costs, but factory-made parts can be.

Cast in situ or Precast Concrete! Which one is a Better method Civil Rack

In-situ cast construction is a quite complex process with many inputs and flows; e.g. material, components, and equipment have to be transported to and on the site, tasks have to be performed in certain sequences, etc. One may ask whether industrial in-situ cast concrete building is a paradox, or whether it is

Builtconstruct Different Castinsitu Methods of Bridge Construction

Cast-in-situ concrete, also known as cast in place meaning, is prepared, placed, and finished on the construction site. This process, often referred to as concrete casting meaning, involves casting of concrete directly where it is required. Generally, concrete slabs, concrete foundations, beam, column, wall, roof, etc., are preferred structures in cast-in-situ concrete.

Driven Cast InSitu Piling at London Gateway YouTube

Cast-in-place Concrete, often known as poured-in-place or cast in situ, is a method of concreting that is carried out in situ, or in the finished location of the concrete component. It is a method of constructing in which the walls and slabs of the buildings are cast on-site in formwork.